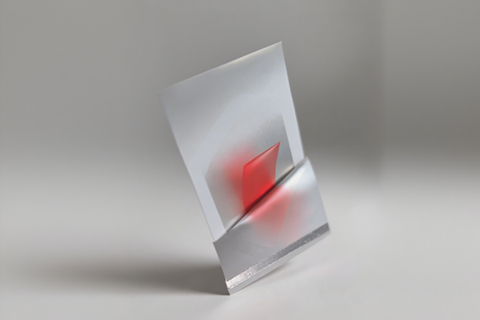

ODF Casting & Drying Line

Servo-driven slot-die or comma-coater, HEPA-filtered drying tunnel, in-line thickness gauge.

From lab-scale coating and casting to commercial ODF production lines, we deliver the equipment, contract manufacturing, and know-how to launch or scale orodispersible films for Rx, OTC, nutraceutical, and veterinary applications.

Turnkey equipment for oral dissolving film manufacturing with tight control of viscosity, wet thickness, drying profile, nip pressure, and web handling.

Servo-driven slot-die or comma-coater, HEPA-filtered drying tunnel, in-line thickness gauge.

Clean-edge slitting and kiss-cutting for consistent unit-dose oral films.

Moisture-barrier packs for nicotine films, melatonin ODF, caffeine films, and Rx buccal strips.

Clinical to commercial batches of oral dissolving films with full batch records.

Polymer selection, plasticizers, sweeteners, taste masking, and API loading.

Factory acceptance, site acceptance, SOPs, and operator training.

Planned service, spare parts, and upgrades for ODF machines & biomedical devices.

Consistent dose for NRT.

Great mouthfeel and fast dissolve.

Convenient energy micro-doses.

Rapid onset with taste masking.